5 Essential Tips to Optimize Your CNC Turning and Milling Processes for Better Efficiency

In the ever-evolving landscape of manufacturing, optimizing processes is key to maintaining competitiveness and achieving operational excellence. Among the various methods employed in modern machining, CNC turning and milling are pivotal techniques that significantly enhance precision and efficiency in production. However, to truly harness their potential, it's essential to implement strategies that streamline these processes. This blog will explore five essential tips designed to optimize your CNC turning and milling operations.

By focusing on best practices and innovative approaches, you'll not only improve the efficiency of your machining tasks but also enhance product quality and reduce waste. Whether you are an experienced machinist or a newcomer to the field, understanding these optimization techniques will prove invaluable in maximizing the capabilities of your CNC machinery and achieving better results in your manufacturing endeavors.

Understanding CNC Turning and Milling: A Primer on Key Concepts

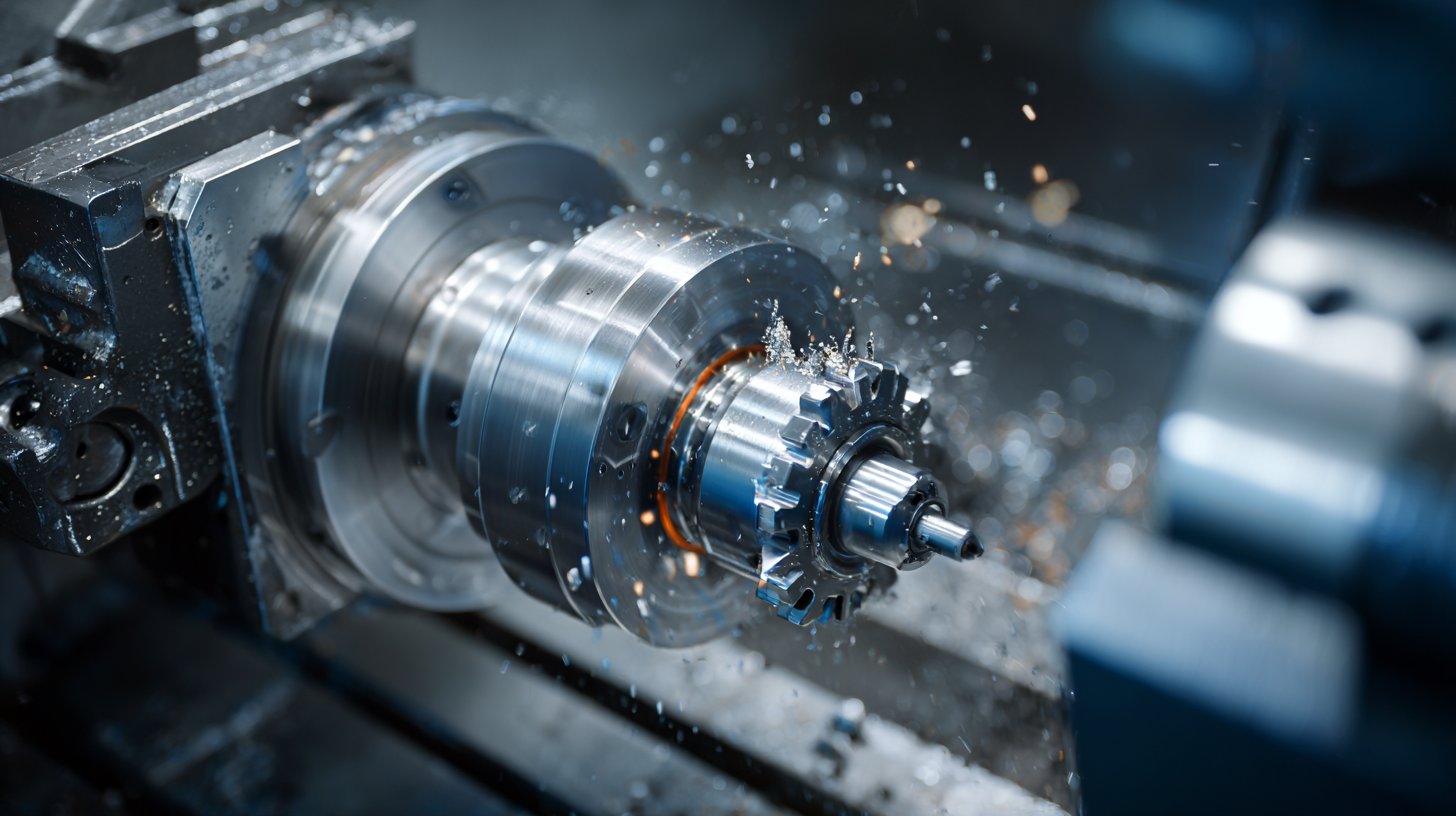

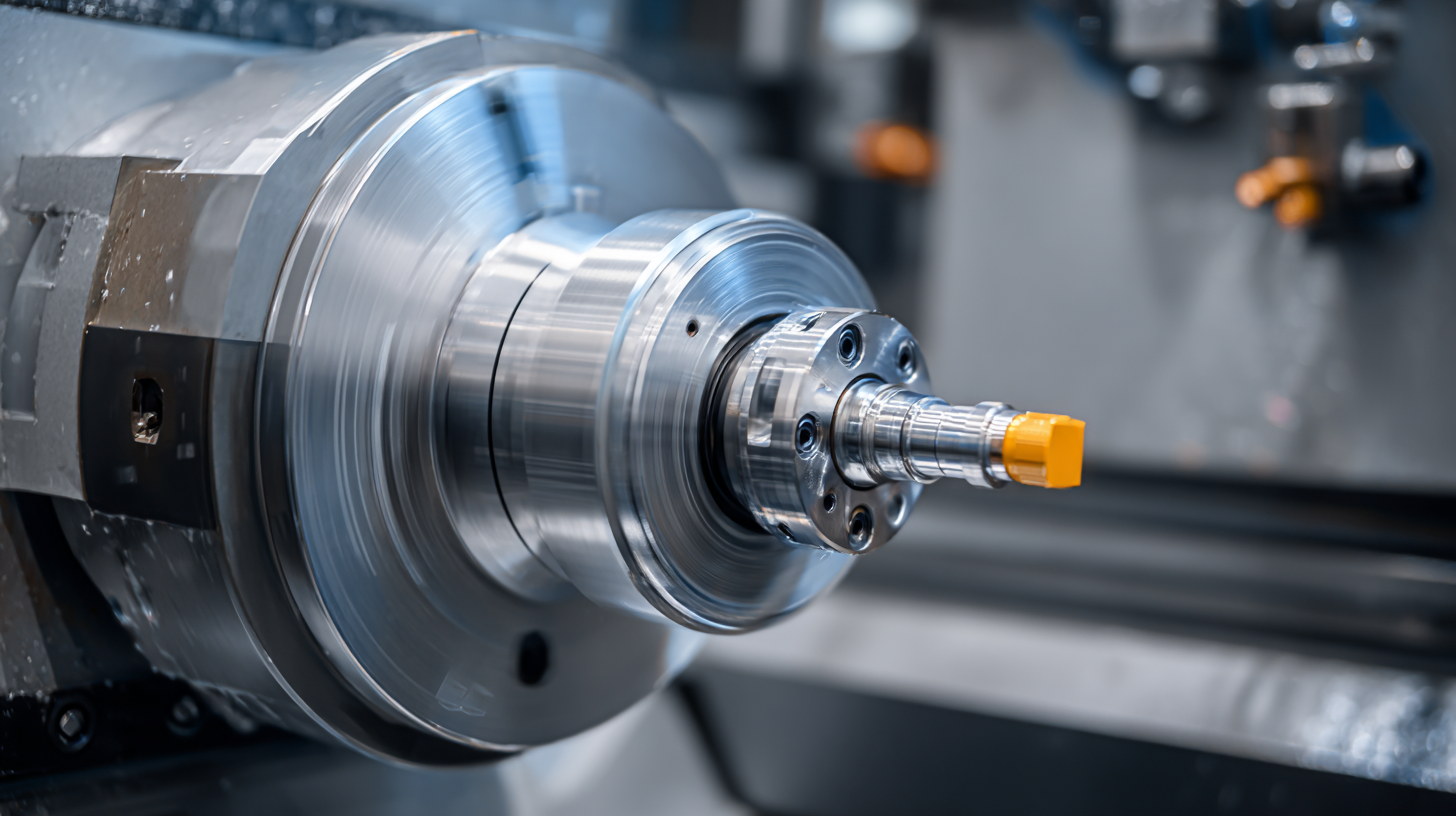

CNC turning and milling are vital processes in the realm of manufacturing, allowing for high precision and efficiency in creating complex parts. CNC, or Computer Numerical Control, enables machines to be programmed to cut and shape materials with exceptional accuracy. Understanding the fundamental concepts of CNC turning, which involves the rotation of a workpiece against a stationary cutting tool, is crucial. This process excels in producing cylindrical parts, showcasing its effectiveness in industries like automotive and aerospace.

Milling, on the other hand, utilizes a rotating cutting tool to remove material from a stationary workpiece. This method is versatile, enabling the creation of intricate shapes and features. Different milling techniques, such as face milling and end milling, provide manufacturers with various options to meet specific production needs. By grasping these foundational concepts, practitioners can better appreciate how CNC technology enhances overall productivity and fosters innovation in modern manufacturing. Each process has its unique set of capabilities and applications, making it essential for engineers and operators to understand their intricacies for optimizing production efficiency.

Optimizing CNC Turning and Milling Processes: Efficiency Metrics

Identifying Common Inefficiencies in CNC Processes

When it comes to CNC machining, inefficiencies can significantly hamper productivity and cost-effectiveness. One common issue is the idle time during tool changes. By carefully evaluating the workflow, operators can schedule tool changes during non-cutting periods or utilize automatic tool changers to minimize downtime. Additionally, reducing the setup times through standardized processes can ensure that machines spend more time producing and less time being prepared for new tasks.

Another prevalent inefficiency is due to suboptimal cutting parameters. Many machinists often overlook the importance of using the correct feed rates and spindle speeds for different materials and geometries. Conducting thorough experimentation and utilizing data-driven approaches can lead to optimized parameters that enhance both tool life and surface finish quality. Furthermore, implementing regular machine maintenance checks can prevent unexpected breakdowns and maintain consistent production output. Addressing these common inefficiencies is crucial for maximizing the efficacy of CNC turning and milling processes.

Implementing Advanced Tooling Techniques for Enhanced Performance

Implementing advanced tooling techniques is crucial in optimizing CNC turning and milling processes. According to a report by the National Tooling and Machining Association (NTMA), the adoption of cutting-edge tooling can enhance productivity by up to 30%. By integrating newer materials and geometries in tooling, manufacturers can achieve faster cycle times and superior finish quality, thereby reducing the overall cost per part.

One essential tip to consider is the use of high-performance cutting tools, such as coated carbide inserts, which increase tool life by 40% and improve speed and feed rates. Additionally, implementing adaptive machining technologies enables real-time adjustments based on tool wear and material conditions, leading to more consistent results and less downtime.

Furthermore, leveraging advanced CNC software for simulation and tooling optimization can significantly streamline operations. According to a Deloitte study, firms that adopted such software saw a productivity increase of approximately 25%. By carefully analyzing machining parameters and employing custom fixtures, manufacturers can further enhance efficiency and precision, ensuring that their CNC operations are as effective as possible.

Utilizing Automation and Software Solutions to Streamline Operations

In the realm of CNC turning and milling, the integration of automation and advanced software solutions has become paramount for enhancing operational efficiency. By automating routine tasks, manufacturers can significantly reduce cycle times while minimizing human error. For instance, implementing robotic arms can streamline the loading and unloading processes, allowing machines to operate continuously without unnecessary downtime. This not only increases productivity but also enables operators to focus on more complex tasks that require human oversight or creativity.

Moreover, leveraging sophisticated software tools can further optimize CNC operations. These systems allow for real-time monitoring and data analysis, providing insights into machine performance and operational bottlenecks. With advanced scheduling algorithms, companies can better allocate resources and manage workloads, ensuring that every machine is utilized to its full potential. By embracing these technological advancements, organizations can achieve a seamless workflow that drives both productivity and quality, ultimately leading to a more competitive edge in the manufacturing landscape.

Regular Maintenance Practices for Sustained CNC Machine Efficiency

Regular maintenance is crucial for ensuring sustained efficiency in CNC machines. Implementing a routine maintenance schedule can significantly reduce downtime and extend the life of your equipment. One essential tip is to conduct routine inspections of key components, such as the spindle and bearings. Check for any signs of wear or damage and address them immediately to prevent further complications.

Another important practice is to keep the machine clean and well-lubricated. Accumulated debris and inadequate lubrication can impede performance and accuracy. Ensure that the machine's coolant levels are adequate and that the lubrication system is functioning properly. Regularly changing the coolant and lubricants can also enhance machining results and maintain temperature stability, leading to better overall efficiency.

Additionally, it’s beneficial to train your operators on the best practices for operating and maintaining CNC machines. Well-informed staff can spot potential issues early and follow maintenance protocols effectively, ensuring peak machine performance. Delving into these regular maintenance practices will not only optimize your CNC turning and milling processes but also enhance long-term productivity.

5 Essential Tips to Optimize Your CNC Turning and Milling Processes for Better Efficiency

| Tip | Description | Frequency | Impact on Efficiency |

|---|---|---|---|

| Regular Lubrication | Ensures smooth operation of moving parts, reducing wear and tear. | Weekly | High |

| Tool Inspection | Regular checks on tools for wear to prevent defects in finished products. | Daily | Medium |

| Calibration | Ensures machines maintain accuracy and precision in production. | Monthly | High |

| Cleaning | Keeps machine parts free from debris, promoting better performance. | Weekly | Medium |

| Software Updates | Ensures machines operate with the latest features and bug fixes. | Quarterly | High |

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219