Exploring the 2025 Tech Revolution: Advantages of the Best CNC Turning Solutions

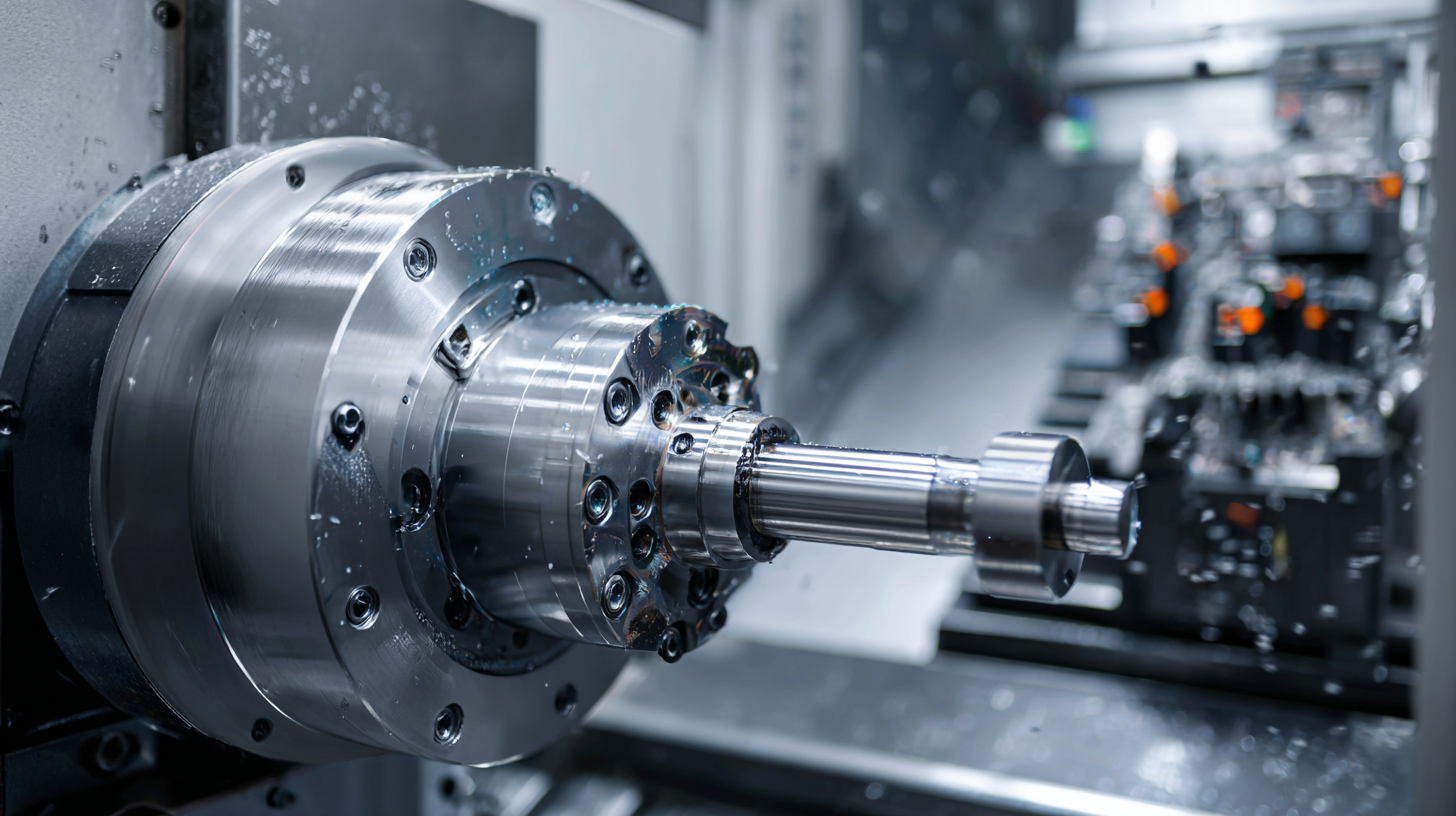

As we stand on the brink of a technological revolution in 2025, the landscape of manufacturing is poised for transformative changes, driven by advanced solutions like CNC turning. This innovative machining process not only enhances precision and efficiency but also aligns with the global push for high-quality production. The phrase "中国制造,以品质赢得世界尊重" encapsulates the essence of China's commitment to excellence in manufacturing, and CNC turning stands at the forefront of this movement. By exploring the advantages of the best CNC turning solutions, we can understand how they contribute to maintaining competitive edge and fostering respect in the global market. As industries evolve, embracing cutting-edge technology in CNC turning will be crucial for manufacturers aiming to meet the ever-increasing demands for quality and efficiency while setting the stage for a sustainable future.

Advantages of Adopting CNC Turning Solutions in Modern Manufacturing

In the realm of modern manufacturing, adopting CNC turning solutions has emerged as a pivotal strategy for enhancing productivity and efficiency across various industries. By integrating advanced digital manufacturing technologies, businesses can streamline operations, reduce lead times, and improve product quality. The shift from traditional methods to CNC machining not only optimizes production processes but also allows for greater precision and consistency in the final output, addressing the increasing demands of today’s market.

Furthermore, the incorporation of Industry 4.0 innovations such as AI and real-time monitoring systems transforms shop floor dynamics. Controls facilitate better oversight and adaptability, enabling employees to harness these advancements effectively. As the manufacturing landscape evolves, companies embracing CNC turning solutions can achieve significant strategic advantages, positioning themselves at the forefront of the tech revolution set to shape future industries. By leveraging these cutting-edge techniques, manufacturers are not just keeping pace with technological advancements but are also pioneering innovative practices that redefine production standards.

Exploring the 2025 Tech Revolution: Advantages of the Best CNC Turning Solutions

| Feature | Description | Advantages | Impact on Manufacturing |

|---|---|---|---|

| Precision Machining | Automated processes that provide high accuracy in production. | Minimizes waste and ensures product consistency. | Enhances quality control and reduces rework costs. |

| Operational Efficiency | Streamlined workflows with CNC automation. | Faster production times and reduced labor costs. | Increases throughput and maximizes resource utilization. |

| Customization Capabilities | Flexible programming options for unique designs. | Enables rapid response to market demands. | Empowers manufacturers to cater to niche markets. |

| Reduced Setup Time | Quicker changeovers between jobs with CNC tools. | Decreases downtime and maximizes productivity. | Improves overall operational efficiency. |

| Data Integration | Real-time data tracking and analytics. | Informed decision-making based on accurate data. | Enhances process optimization and future planning. |

Key Industry Trends Driving the Next Tech Revolution in CNC Machining

The landscape of CNC machining is undergoing a significant transformation, shaped by emerging technologies and evolving industry demands. According to a report by MarketsandMarkets, the CNC machining market is projected to reach USD 100.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2% from 2020. This growth is fueled by key trends such as the integration of IoT devices and advanced automation, which enhance operational efficiency and facilitate real-time data analytics. Manufacturers are increasingly adopting these innovations to optimize their CNC turning solutions, allowing for quicker responses to market changes and reduced downtime.

Furthermore, the shift towards sustainability and environmentally friendly practices is influencing CNC machining. A study by McKinsey indicates that more than 60% of firms are expected to invest in green technologies by 2025. This trend is prompting CNC operators to rethink their processes, focusing on energy-efficient machines and eco-friendly materials that not only meet regulatory standards but also attract a growing consumer base that values sustainability. As the industry evolves, staying ahead of these trends will be crucial for companies aiming to leverage the advantages of advanced CNC turning solutions in the forthcoming tech revolution.

Data-Driven Insights: Increasing Efficiency with CNC Turning Technology

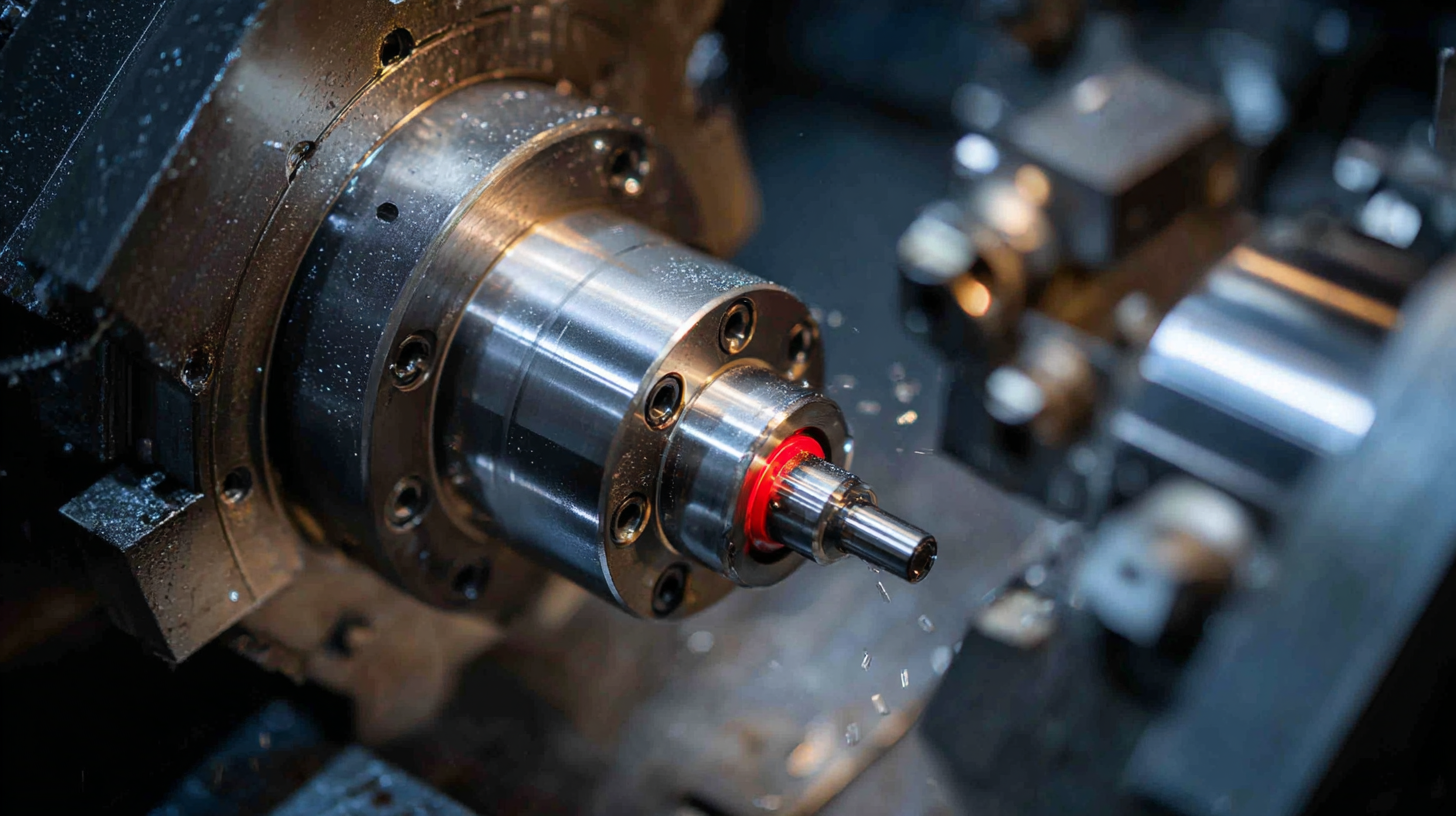

CNC turning technology is revolutionizing the manufacturing landscape by leveraging data-driven insights to enhance efficiency and productivity. The integration of advanced analytics allows manufacturers to optimize their processes, reducing waste and downtime. With real-time data monitoring, operators can quickly identify bottlenecks and implement corrective measures, ensuring smooth operations throughout the production cycle.

Moreover, the rise of Industry 4.0 has enabled CNC turning machines to connect to the internet, facilitating the collection and analysis of vast amounts of operational data. This connectivity provides valuable insights into equipment performance, enabling predictive maintenance and minimizing unexpected failures. As a result, businesses can achieve higher levels of output while maintaining quality standards, ultimately driving down costs and improving profitability. By harnessing these data-driven insights, manufacturers are well-positioned to adapt to the fast-paced changes of the tech revolution in 2025 and beyond.

Cost Savings and Precision: The Financial Benefits of CNC Turning Solutions

In the rapidly evolving landscape of technology, CNC turning solutions are becoming increasingly vital in various industries. These advanced machining processes not only enhance productivity but also translate into significant cost savings for businesses. By automating turning operations, manufacturers can minimize material waste and reduce labor costs, ultimately leading to a better bottom line. The precision offered by CNC technology ensures that components are produced to exact specifications, reducing the need for costly reworks and ensuring high-quality outputs.

When considering the financial benefits of CNC turning, it's essential to choose the right equipment. Investing in high-quality CNC lathes can yield long-term savings through reduced maintenance and operational efficiency. Additionally, keeping up with software updates and training for your team can further maximize the capabilities of your CNC machines.

To optimize the benefits of CNC turning, consider streamlining your supply chain. By integrating your CNC solutions with inventory management systems, you can better predict your material needs, thus minimizing excess stock and associated holding costs. Regularly reviewing your production process can also highlight areas for improvement, helping to maintain the financial advantages that CNC turning brings to your operations.

Future Innovations: The Role of AI and Automation in CNC Turning Systems

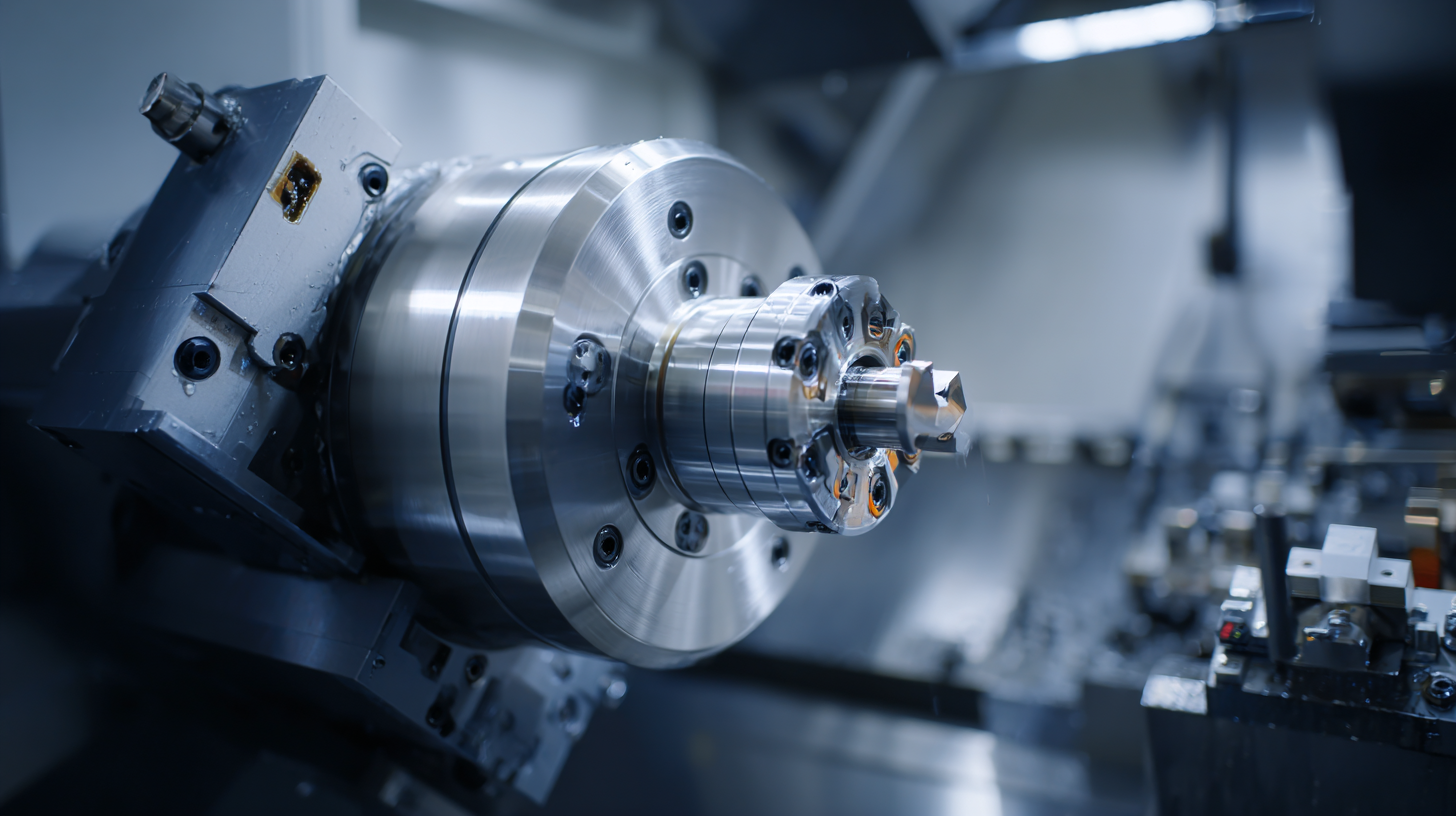

As we venture into the 2025 tech revolution, artificial intelligence (AI) and automation are poised to revolutionize CNC turning systems. These technologies not only enhance precision but also streamline manufacturing processes, making it easier for industries to meet increasing demands. AI-driven algorithms can analyze vast amounts of data in real-time, enabling CNC systems to adapt to changing conditions and optimize their operations on the fly. This leads to increased efficiency, reduced waste, and significant cost savings for manufacturers.

Moreover, the integration of automation within CNC turning solutions offers greater flexibility. By utilizing robotic arms and automated tool changers, manufacturers can achieve quicker turnaround times and operate their machines around the clock. The synergy between AI and automation ensures that these systems are not just reactive but also proactive, predicting maintenance needs and minimizing downtime. This capability not only bolsters productivity but also allows manufacturers to focus on innovation, ultimately driving the industry forward in an era defined by technological advancement.

Exploring the 2025 Tech Revolution: Advantages of the Best CNC Turning Solutions

This chart illustrates the potential efficiency gains from adopting advanced CNC turning solutions, highlighting the roles of AI and Automation in enhancing production processes by the year 2025.

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219